PREMIUM QUALITY, INNOVATIVE AND

CUSTOM MADE SPORTS APPAREL & ACCESSORIES

ABOUT US

SpoStar International is the manufacturer of Premium Quality, Innovative and Custom made Sports Apparel and Accessories using exceptional material.

As an owner-operated company, we are able to provide a higher level of service and accountability to our clients through direct communication. Our aim is to create an elevated experience that goes beyond the industry norm for every client. We have taken our knowledge and expertise in the apparel industry, along with our philosophy of superior service, to create products that enhance our client’s identity.

SCREEN PRINTING

It is one of the fastest way of printing verity of designs on clothing. With great detail, and durable material used, our customers are satisfied with the long lasting material.

EMBROIDERY

Embroidery is a process of stitching threads on top of clothing, or accessories. With variety of options available for you to choose, we are capable of providing bulk quantities to our customers needs.

DTG

DTG/DTF (Direct to Garment/Fabric) is a process of printing on top of apparels & direct to fabric, or accessories. With variety of options available for you to choose.

SUBLIMATION

A process of printing to polyester that provides the most durable printing option. transfers the dyes onto the fabric at a molecular level, essentially meaning the ink and the fabric are now one indistinguishable item, rather than the dye sitting on the fabric to simply wash off.

LASER PRINTING

Laser printing is an electrostatic digital printing process. It produces high-quality text and graphics (and moderate-quality photographs) by repeatedly passing a laser beam back and forth over a negatively-charged cylinder called a "drum" to define a differentially-charged image. Laser printing on fabric is similar to printing on an inkjet, except you needn't treat the fabric beforehand.

LOGO DESIGNING

With logo design, you have a visual communication tool to help you get your message across to the audience. Logos are composed of text, color, shape, and illustrations. It serves as a self-explanatory image that people can use to connect with your brand. We are providing free logo design services for your brands and clubs.

HEAT PRESS

A heat press is a type of machine that utilizes heat in order to apply designs onto various substrates. The majority of presses are used to apply heat transfers onto a range of garments.A heat press will apply a transfer under pressure, and at a high temperature, for a pre-set amount of time. It gives you a reliable, professional application that should last for the lifetime of the garment.

CUSTOM MANUFACTURING

Apparel manufactures custom clothing for small and large brands and businesses. We are a one-stop custom apparel manufacturer that provides you with any type of specifications you want your clothing line with a wide range of apparel production experience. We aim to deliver high-quality services and help our clients with every type of customization they are looking for.

OUR WORKFLOW

Pattern Making

Patterns are designed according to required sizes and designs, each article has a different pattern, they are designed with accuracy and precision.

Pre-Production Sample

Before bulk production, we get your approval by making sample and ship it to you. Once approved we move to the next step.

Material & Fabric Sourcing

Fabric is sourced from most reliable and recommended fabric suppliers. The fabric is stored in the fabric store in racks. Fabric inspection is done prior shifting it to cutting department.

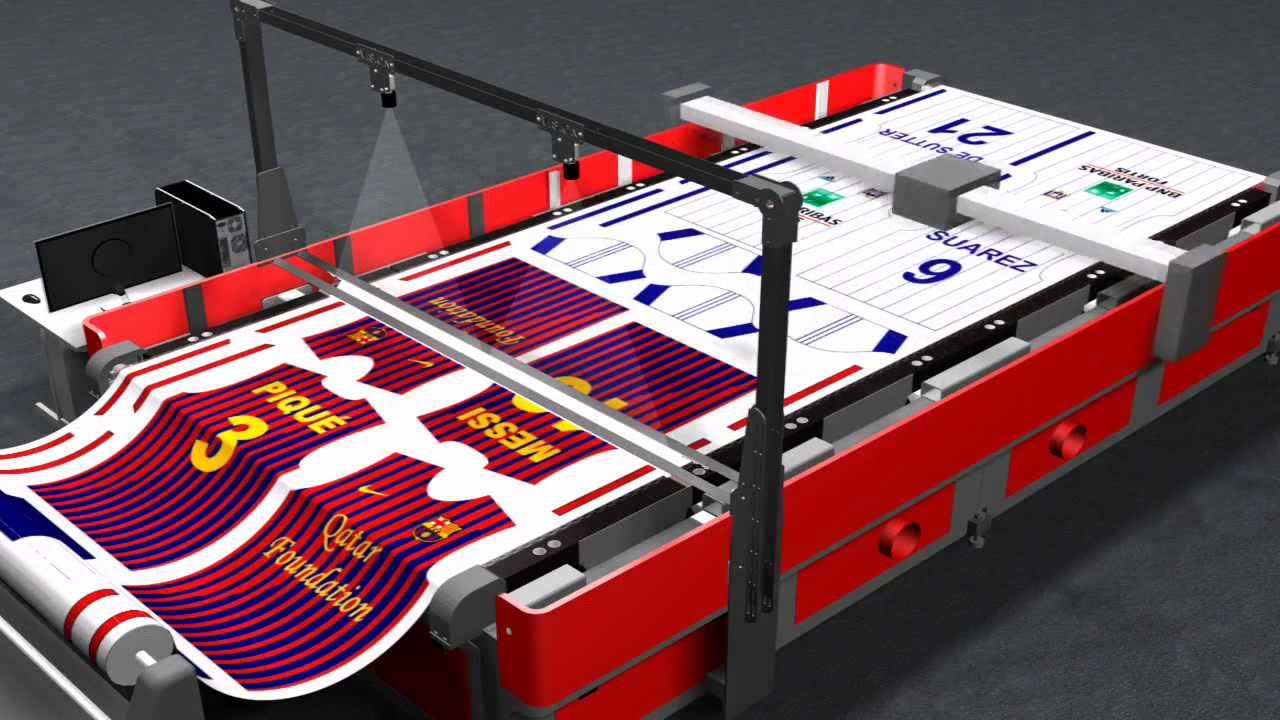

Cutting & Printing Process

After sourcing, the fabric is cut down into pieces according to the patterns. After that, these pieces have printing or embroidery on them as required by our customers.

Sewing & Quality Check

Cut panels are then sewed together and the design finally comes to life. After that, all items are carefully inspected to ensure the highest quality standards so that we can remain one of the best sportswear and activewear manufacturer.

Packing & Delivery

After that all items are pressed, tags are installed on them and after that they are packed in poly bags. Finally, all items get packed in carton and are finally shipped using reliable delivery services.

OUR WORKFLOW

Pattern Making

Patterns are designed according to required sizes and designs, each article has a different pattern, they are designed with accuracy and precision.

Pre-Production Sample

Before bulk production, we get your approval by making sample and ship it to you. Once approved we move to the next step.

Material & Fabric Sourcing

Fabric is sourced from most reliable and recommended fabric suppliers. The fabric is stored in the fabric store in racks. Fabric inspection is done prior shifting it to cutting department.

Cutting & Printing Process

After sourcing, the fabric is cut down into pieces according to the patterns. After that, these pieces have printing or embroidery on them as required by our customers.

Sewing & Quality Check

Cut panels are then sewed together and the design finally comes to life. After that, all items are carefully inspected to ensure the highest quality standards so that we can remain one of the best sportswear and activewear manufacturer.

Packing & Delivery

After that all items are pressed, tags are installed on them and after that they are packed in poly bags. Finally, all items get packed in carton and are finally shipped using reliable delivery services.

OUR CERTIFICATES

COMPLETED ORDER